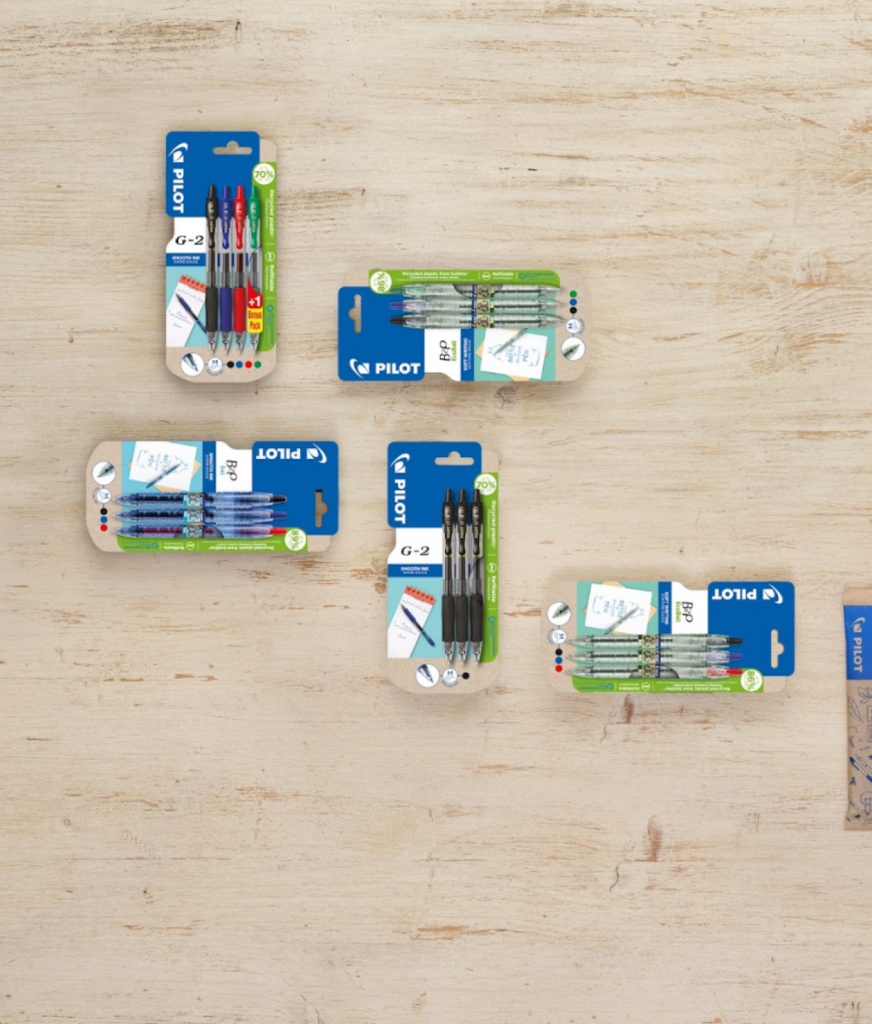

Begreen

Recycled Products

* % of recycled material, excluding consumables.

At PILOT, we do whatever it takes to prevent industrial risk and to limit all forms of pollution linked to our activities. Pilot Corporation of Europe, located in France, in compliant with the legislation about plastic granules pollution limitation. Studies are constantly being undertaken to ensure our factories consume the least possible resources: whether water, gas, or electricity.

All products distributed in Europe come from PILOT factories. This enables us to control every stage in the manufacture of products, taking into account their environmental impact.

Our environmental vision is only meaningful if it is shared by everyone, and we are very proud to say that 100% of our employees are involved in our environmental approach.

We also make sure that our external partners share our values and convictions. Our distributors and consumers are always informed of our environmental goals and results via an environmental declaration.

The magicians are our engineers and R&D departments. They constantly innovate to reduce the use of virgin raw materials.

Since 2020, our 2 best-sellers, FriXion and G-2, have been manufactured with a minimum of 50% of recycled plastic, more proof of our desire to act effectively.

Recycling plastic water bottles to turn them into pens is another technological feat and that’s the story behind our B2P range since 2006.

In 2021, we’ll be going even further because for the first time worldwide, that same B2P range will be composed of not only recycled plastic from bottles, but also of plastic waste collected from beaches.

It’s an innovative initiative allowing us to take part at our level in tackling ocean pollution.

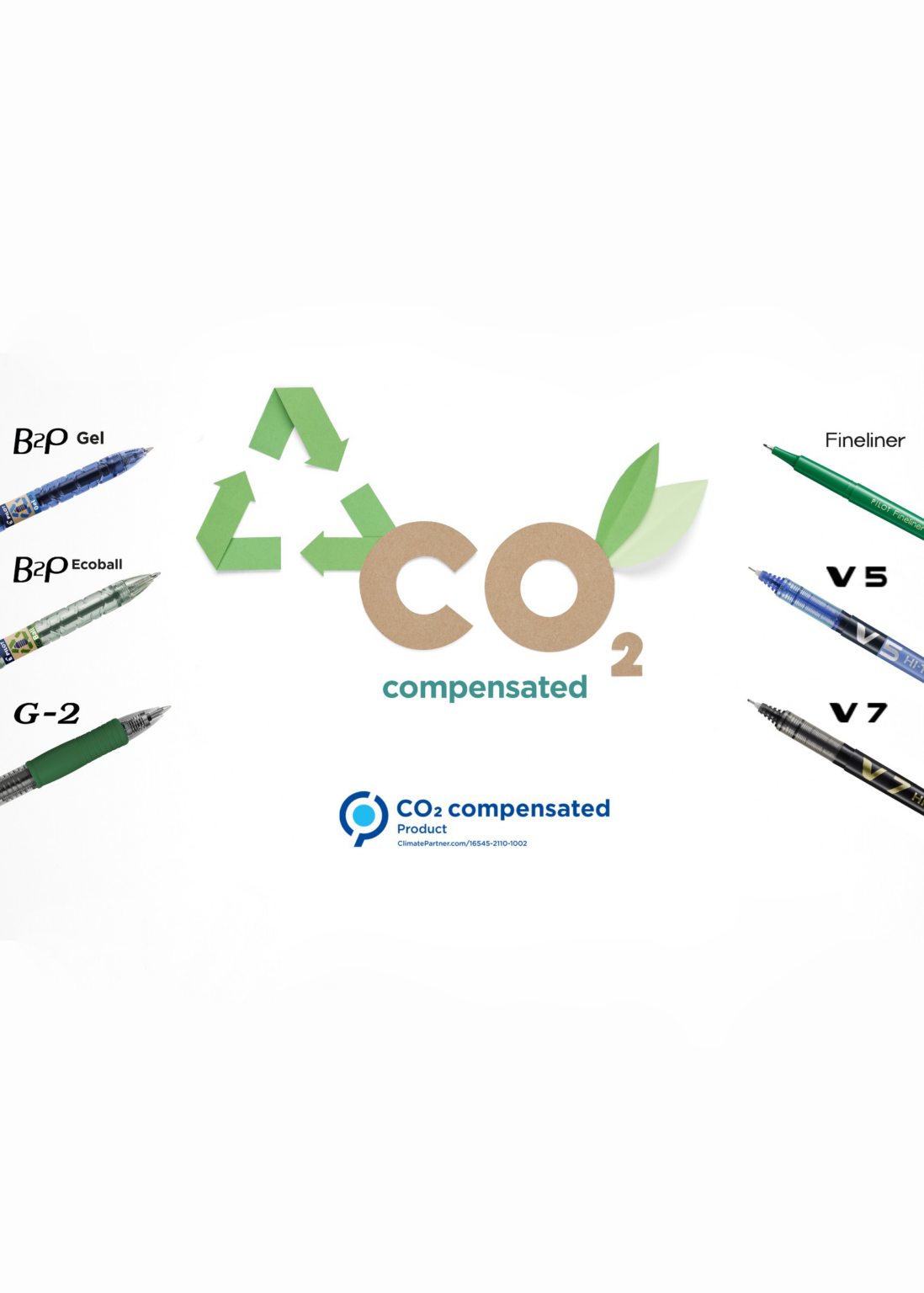

From October 2021, all pens manufactured at Pilot European factory, based in France (74), are CO2 compensated. This means that Pilot compensate their CO2 emissions by supporting a certified carbon offset project.

PILOT has therefore decided to support and fund “Clean Oceans Plastic Bank Worldwide” through a partnership with Climate Partner. Between 8 and 12 million tons of plastic end up in our oceans annually and 70% of such waste sinks to the seabed where we are unlikely to be able to clean it up. The key is to collect plastic before it enters the oceans! And the “Plastic bank project’s” mission is exactly that; to stop plastic waste from entering the oceans.

The EU Eco-Management and Audit Scheme (EMAS) is a premium management instrument developed by the European Commission for companies and other organisations to evaluate, report, and improve their environmental performance.

EMAS is open to every type of organisation eager to improve its environmental performance. It spans all economic and service sectors and is applicable worldwide. More information on: https://ec.europa.eu/

Standard relating to the environmental management of companies. This involves measuring a company’s environmental impact, establishing improvement objectives and measuring their success.

This certification, renewable every two years, requires continuous improvement of the company’s environmental impact. This standard is not related to the products, but more particularly the production process.